When I was recovering from a hernia operation I designed a clock around an Arduino, real time clock board and temperature/humidity sensor. This was built onto breadboard and was as flaky as hell due to poor connections.

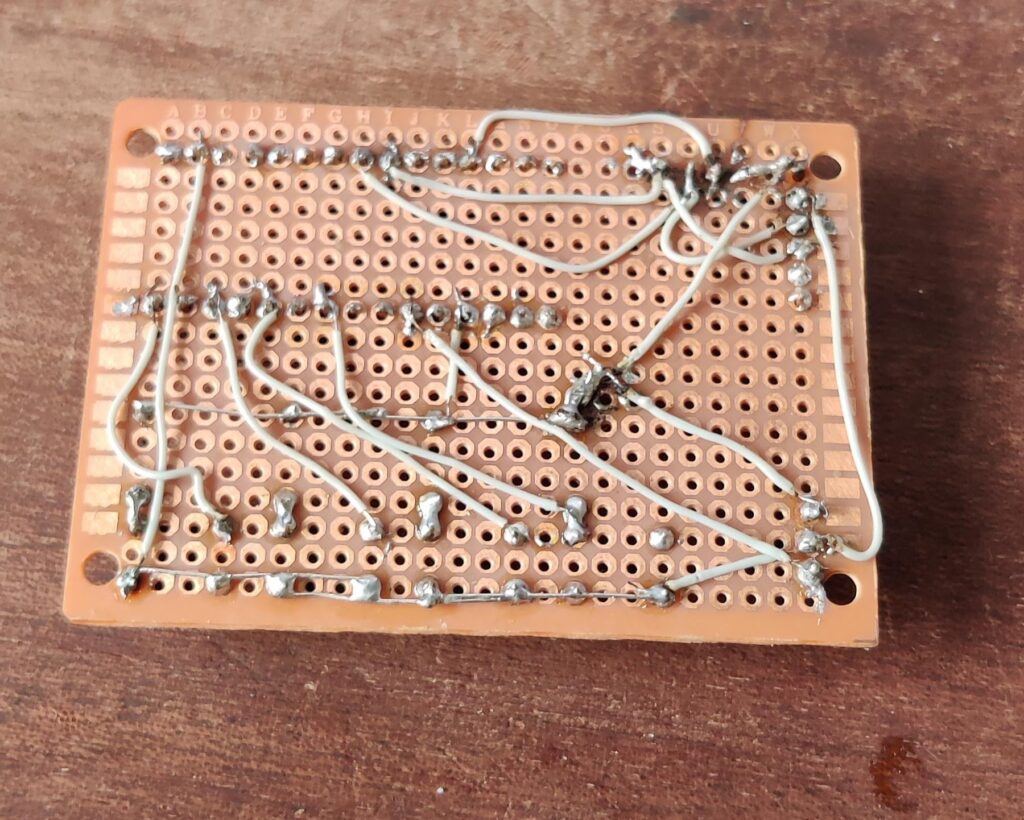

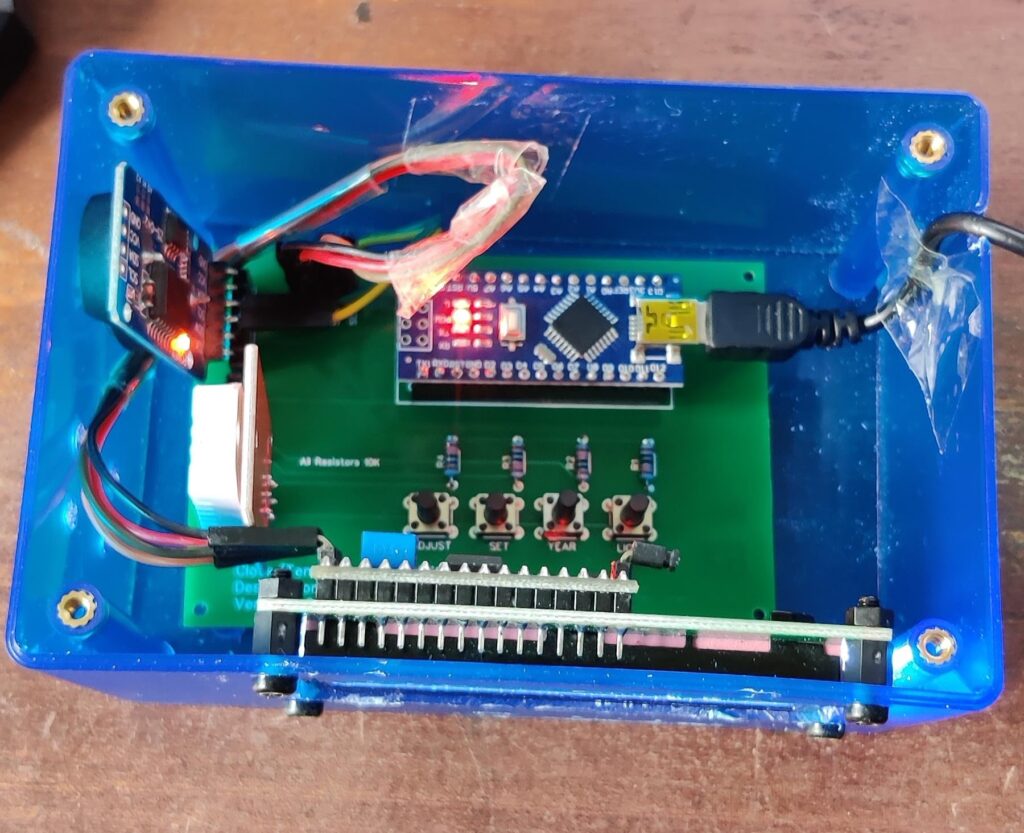

Recently I decided to build the project using perfboard, which is messy and caused 2 magic smoke release incidents, and bought a case to keep it all looking tidy.

Did I mention perfboard was messy?

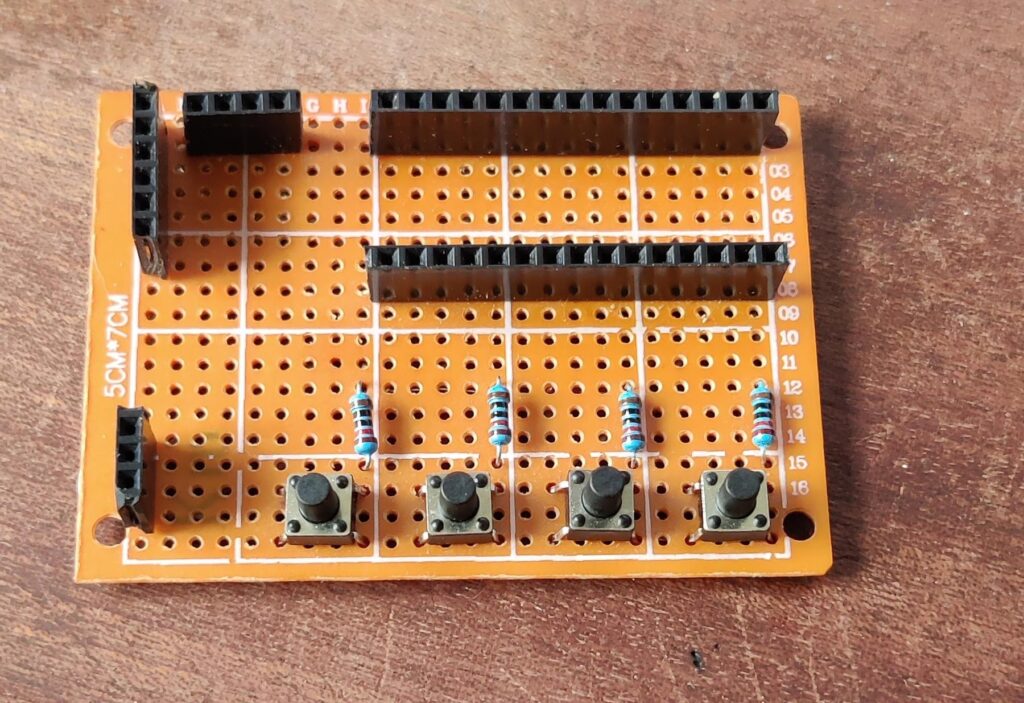

The top does look a bit cleaner.

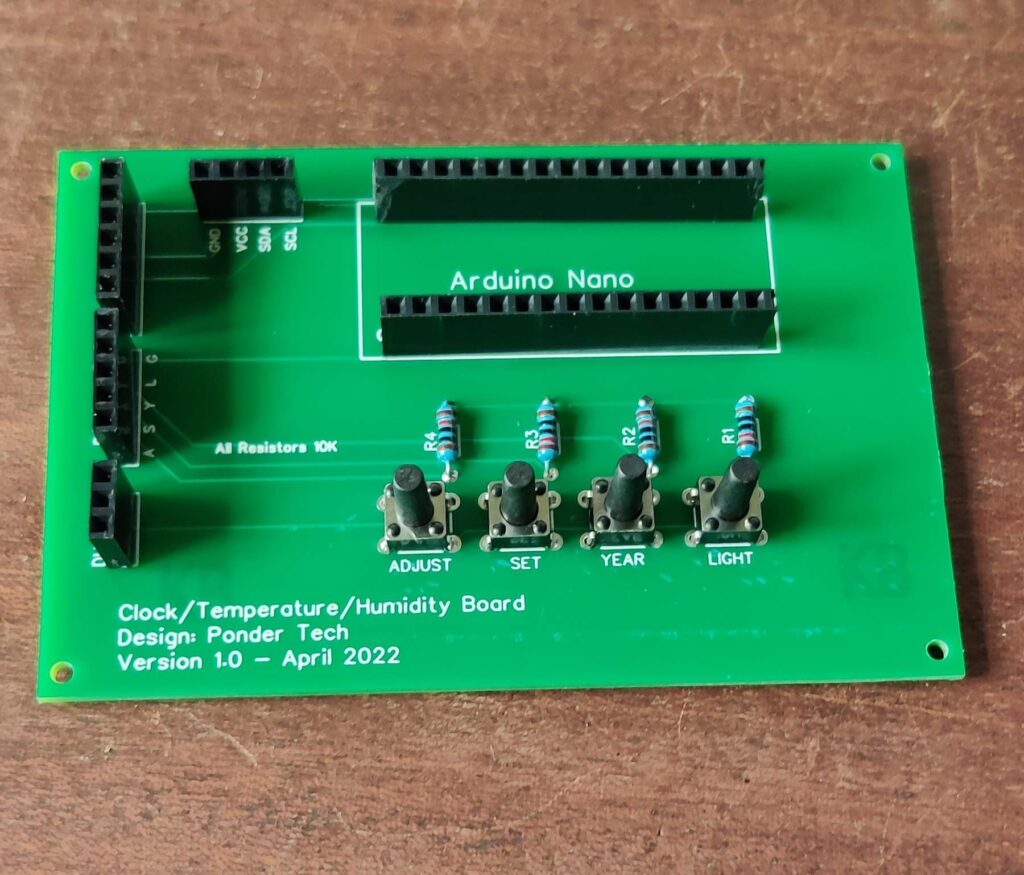

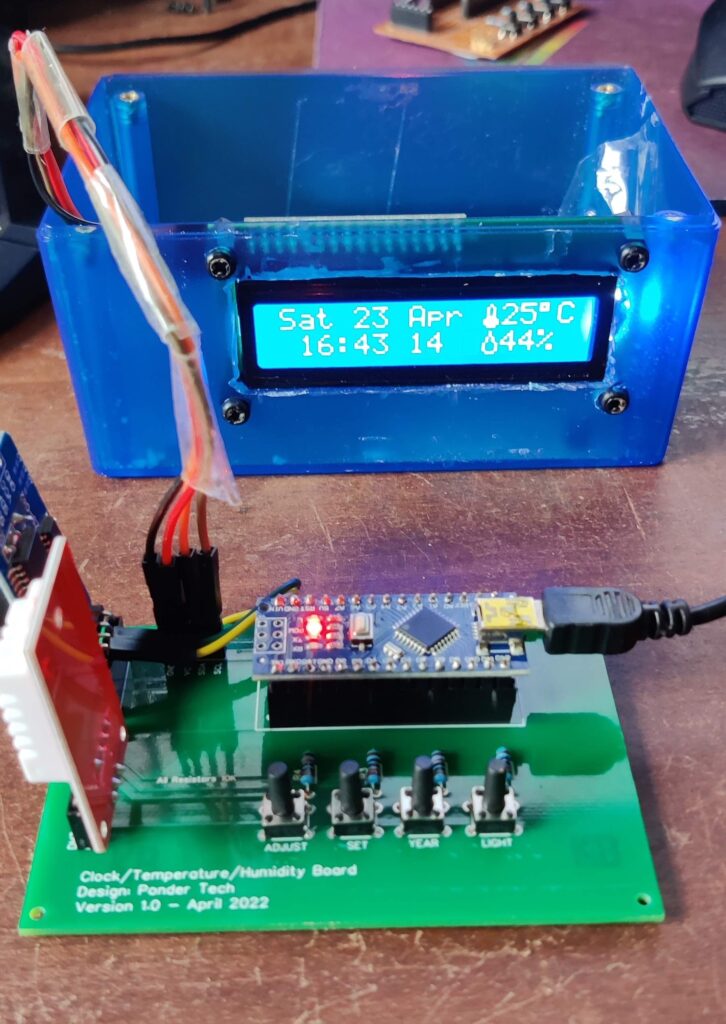

I decided to try my hand at PCB design so I got to grips with that at EasyEDA and sent of the design to PCBWay for production. A few weeks later I had 11 prototype PCBs.

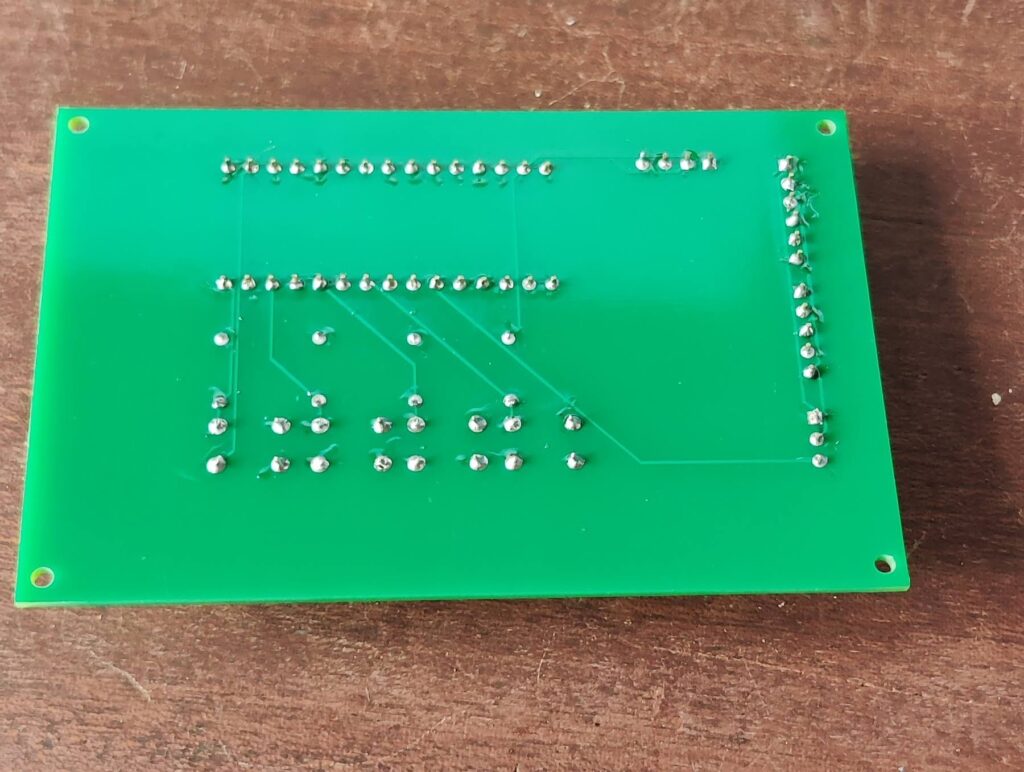

The PCB wasn’t perfect (my fault). The silkscreen was slightly wrong and I found out after build that the SDA and SCL connections were reversed.

I patched the cock-up and everything worked!

Then I added some external buttons and all is complete!

I have corrected the PCB design and gave it rounded corners, sent off the order and now just await delivery. All in all I’m very pleased with this 🙂

Just below the picture of the PCB upper surface.

You patched up the what?

Filth. Disgusting filth

You say that like it’s a bad thing 😉

Nice. I’ve never had the courage to send off a PCB design. Veroboard all the way for me so far.

It was a big step but one I’m so glad I took!